Electronics manufacturing is a burger of complexity

A retail product is often a neatly wrapped up package that seems whole unto itself. In actuality, and especially in electronics hardware, these are highly complex collections of many smaller products and component pieces, which often have their own complexity (turtles all the way down, or something like that).

Over on the Dragon Innovation blog, there is a post that outlines the various stages of product planning and what goes into making it market ready. The nomenclature is pretty specific to their application, and might not always translate, but the fundamentals are seen in many forms of manufacturing.

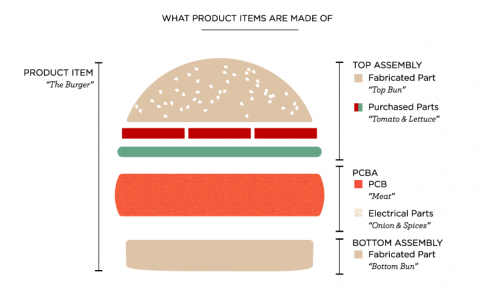

So, for example, at Dragon they have organized a structure where a Product Item is the thing that you buy, but within that there are multiple parts, as shown in this cute burger (vegetarian I hope) graphic.

Managing all of these parts as a manufacturer and retailer is a huge challenge and there is a a lot of money in planning around all these intricacies and specificities, whether its ERPs, or PLMs. Dragon Innovation is a company in this game, and on their blog they post something halfway between an advertisement and a great general overview of what goes into this process.

A little bit from their post:

About Accessories

So what’s considered an accessory? Well, it’s something that’s not the main part of the product, but certainly would be missed if it wasn’t there. Who wants a burger with no fries? This would be anything that doesn’t have a PCB or PCBA that enhances the usability of your product. They could be either fabricated or existing parts.

- Examples Include:

- Power cable

- Stand

- Screen wipe

- Straps/Hooks

How Product Planner Helps to Manage Accessories

Each SKU Provides a BOM line item for an Accessories List; inside of this list you can attach as many parts or BOMs you’d consider an accessory as needed. Since any of the items inside of the Accessory List is a part or assembly, you can manage Minimum Order Quantity (MOQ), suppliers, costs, and lead times just as you would any other part. This makes it easier for teammates and possible factories to visualize that this part of the SKU holds supportive functionality.

At Adafruit we see all of this complexity firsthand and on a daily basis. And where we once had an ad hoc product management system that carried us for a long time, we really benefited from incorporating a holistic PLM system, event if it wasn’t the easiest transition (hint: it never is) and really the earlier you can do this, the better.

Check out the whole post to get an appreciation for what goes into manufacturing, and what kind of systems are needed to best manage it.