Engineering a Repairable World

It's time for engineers to champion repair

This is a guest post. The views expressed here are solely those of the author and do not represent positions of IEEE Spectrum or the IEEE.

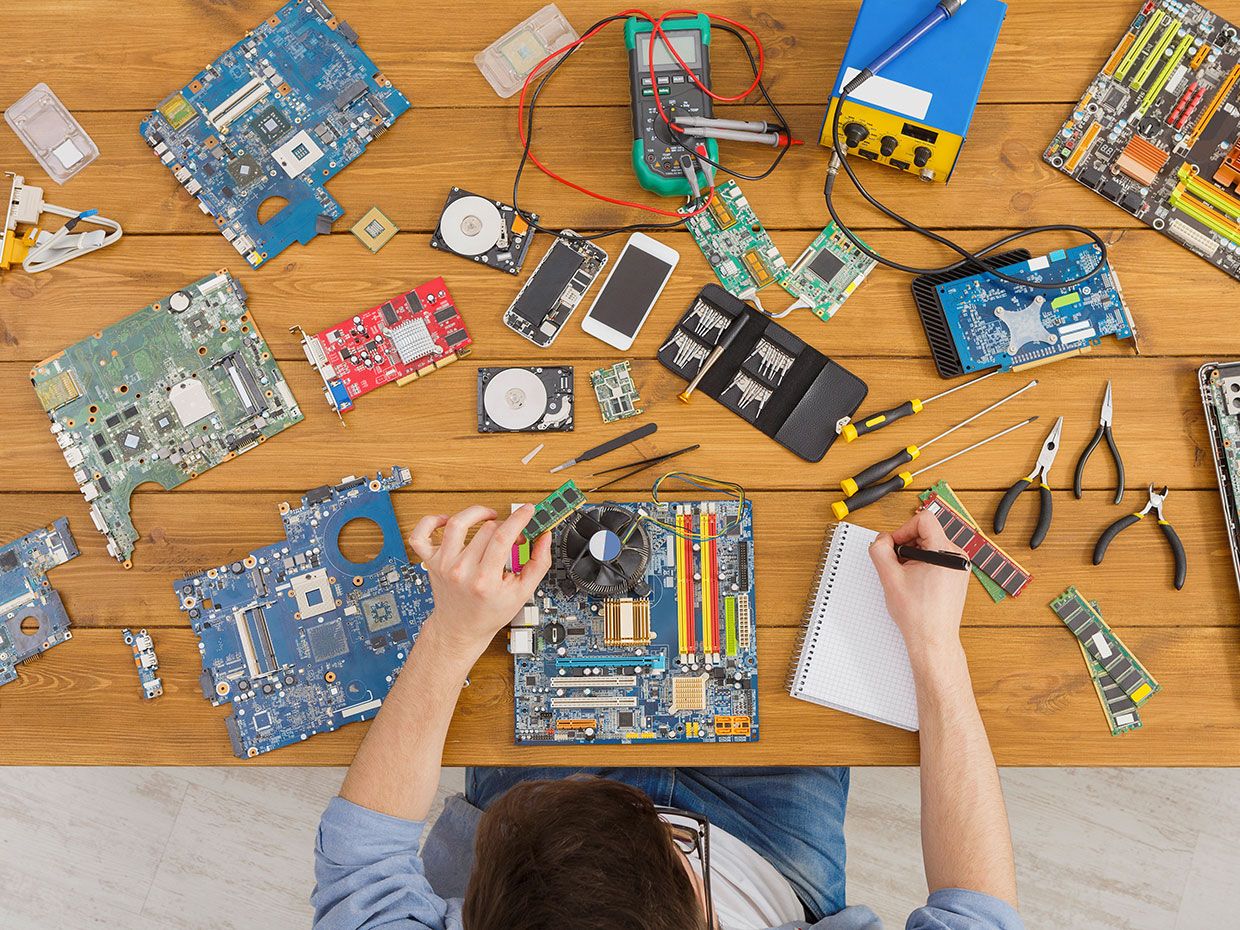

We are surrounded by digital electronics that are getting harder and harder to fix.

As manufacturers have built and sold us more and more devices, they have constructed barriers to fixing them. Schematics and repair diagrams, once widely distributed, are now considered proprietary. Software locks prevent the repair of devices small and large, from tablets to tractors, including coffee makers.

This trend is worrying engineers, many of whom tinkered with their broken stuff as children. As a former engineer myself, I met countless colleagues who were able to point to repair as the start of their interest in the field.

Repair is an important source of instruction and inspiration. And if we lose our ability to fix our devices, an important pipeline of young minds into the engineering world could be forced shut.

Once those young minds do decide to become engineers, the impact of the technology they design and build has consequences on real people’s lives. When a Nebraska farmer is unable to fix a broken fertilizer spreader, for example, his crop, and therefore his livelihood, can hang in balance.

That’s why we need to view repair, not only as an entryway to the field, but also as an essential or even ethical element of sustainable design and engineering.

A New Generation of Tinkerers

Surya Raghavendran's story demonstrates the power of repair to inspire. When Surya was in the 9th grade, he dropped his iPhone 5c and cracked the screen. He paid US$120 for a screen replacement at an Apple store, but a faulty part prevented his screen from working for long.

Surya could have brought the phone back to the Apple store, but not wanting his parents to think he was being careless with the phone, he decided to fix it himself. He watched DIY YouTube videos and bought the parts and tools necessary to complete the repair. Before long, he had mastered the process and started his own business repairing his classmates’ broken screens for about half the price that the Apple store charged him.

Repair allowed Surya to fix his phone and become an entrepreneur in high school. But more than that, it sparked an interest in engineering, which he now studies at the University of Wisconsin.

Stories like Surya’s are now at risk, with many manufacturers, including Apple, refusing to provide the public with the parts, tools, and information needed to repair their devices. Luckily, because Apple has a large user base and makes a limited number of phone models, there is enough of a community to troubleshoot iPhone problems, create instructions to fix them, and even find third-party replacement parts. Users of Android phones, with hundreds of phone models, aren’t so lucky.

To ensure that future Suryas can get their start, we need manufacturers to provide the public with the essential elements of repair. Right to Repair reforms would mandate this, helping to create a tech space friendly to curiosity and learning. But the impact of today’s restrictive repair environment goes beyond our students.

Right to Repair in the Cornfield

Across the heartland of America, farmers are similarly throwing up their hands in frustration. Despite their years of practical experience, they are increasingly unable to fix much of their equipment, threatening their ability to hit razor-thin planting and harvesting windows.

Again, know-how is not the problem—the rise of software in agricultural equipment is preventing repair. Functions that used to have an analog equivalent are now controlled by a central computing system. This provides some conveniences to farmers, such as adjusting certain settings that used to require getting out of the cabin, now with controls at their fingertips.

But along with this change came a significant number of points of failure. Settings that used to be determined by the turn of a valve now use controllers, software, wiring, sensors, and actuators. If any one of those goes down, a whole function is lost. When that happens, farmers are out of luck—only original-equipment manufacturers have access to the diagnostic software required to identify the issue preventing the device from operating correctly. Without these diagnostic tools or other repair information, there is often nothing that a farmer can do to fix the problem on the spot.

Instead, farmers have to take their machine into a dealership. This exposes them to high costs and wait times that the manufacturer’s repair monopoly enables.

Jared Wilson, a Nebraska farmer, talked about one such incident with Nathan Proctor, U.S. PIRG’s Right to Repair campaign director. Shortly after loading up his John Deere fertilizer spreader, a problem developed. The machine was unable to create the hydraulic pressure needed to work properly.

Jared remembers hauling the machine into his dealer, where it sat full of fertilizer for 32 days. He said he called daily and spoke with the manager in person twice. In the time that he could have fertilized 10,000 hectares of land, the dealer found and fixed a mechanical valve that failed. This was the kind of problem that Jared said he could have fixed himself.

Teaching Repairability

When creating equipment for farmers like Jared, engineers start with the problem that needs to be solved. Jared is not able to spread enough fertilizer fast enough, so engineers design a machine that can solve this problem at scale.

But the problem of fixing the device itself can often be overlooked. That’s why iFixit, the self-proclaimed online repair manual for everything, has teamed up with 80 universities around the world to instill the importance of repairability.

Over the course of a term, students in the program take electronic gadgets apart, identify common problems, and build repair guides that are then included in iFixit’s database. This allows them to acquire hands-on experience with everything from home appliances to the latest laptop.

Beyond technical writing and hands-on repair experience, students get exposure to how design decisions impact the lifespan of a given device. The use of adhesives, for example, might allow a cell phone to be a few millimeters thinner than one using traditional fasteners, but it presents real problems for repair and recycling. Is a slightly sleeker device really worth reducing its lifespan or making end-of-lifecycle processing more difficult and less effective?

These are the exact questions that iFixit wants engineering students to be asking. Indeed, they are topics we all should be thinking about.

Right to Repair and the Rest of Us

Despite the best efforts of the iFixit’s technical-writing project, our society is in danger of losing its ability to repair things. Many view the technology we use in our daily lives as almost magical based on the incredible feats they can perform. But this attitude scares lots of us away from opening our devices to fix them when they break.

This ‘fixophobia’ might help convince consumers to pay premium prices for repair or trust the manufacturers pushing upgrades to fixable devices. But at the most basic level, we have lost the agency that should come with ownership. When we buy something, we should have the right to keep it running for as long as we desire.

Due in part to this mentality, many of us now see our devices as disposable. Americans discard roughly 416,000 cell phones every single day. This is one reason that electronic waste is the fastest growing part of our waste stream. Only about 25 percent of materials comprising this e-waste gets recovered in the United States—the rest likely ends up in landfills, where it leaches toxic chemicals into our environment.

The more devices we toss, the more new devices we need to make, which stresses our limited natural resources. Manufacturing a single iPhone 6 requires 295 pounds of raw material. You don’t need to be an environmental engineer to see that we can’t continue this trend forever.

These practices have brought us to a crossroads: We can either continue on this path of unsustainable consumption and manufacturer reliance, or we can forge a new path towards a greener, more independent society.

I want to live in a world where we are conscious of the environmental impact of what we design, build and consume, where we make things that last, fix them when they break, and design them to be modularly upgraded, where we empower people to explore how their devices work, identify weaknesses, and develop ways to improve them, where access to information encourages dialogue so that innovations come from every corner of our society.

Who better to create this world than engineers?

More than 100 engineering professors have started by signing this letter calling for Right to Repair reforms. Join us in creating this world by signing today.

There’s a lot we need to fix. We can start by ditching repair restrictions and enacting the Right to Repair.

Kevin O’Reilly is a legislative advocate with the U.S. Public Interest Research Group (U.S. PIRG).

from Hacker News https://ift.tt/2vs6mS9